PRODUCTS

Optilase specializes in a range of laser applications, including welding, cutting and drilling. With over 20 years' laser applications expertise, our industrial lasers can meet your processing requirements like Laser Welding, Laser Cutting, Laser Drilling, Laser Hardening and Laser Cladding etc.,

Laser Welding

(0.1-6mm Thickness)Our lasers meet the demands of most welding applications. Critical factors include the choice of material, the weld joint design, component part preparation, part fixturing and pre- or post-welding operations.

Laser Cutting

(0.1mm – 10mm Thickness)Laser cutting is a major processing application. Offering high levels of repeatability and reliability, lasers cut a wide range profile cutting at high speed.

Laser Drilling

(0.5mm – 20mm Thickness)It is possible to machine small, unusually shaped holes, blind and precisely tapered holes using lasers. Lasers are also used to process difficult-to-machine materials and drill holes at steep angles.

Laser Hardening

Apart from the classical techniques of laser cutting and laser welding, lasers are used for surface treatment. Surface treatment is a collective term for applications where the laser radiation does not penetrate the material very deeply. This type of surface treatment is characterized by the fact that it changes the mechanical properties of an existing component.

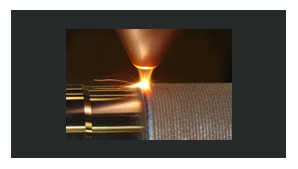

Laser Cladding

Laser cladding is a fusion of the different material to a substrate surface with the minimum of melting of the substrate. The surface alloy composition must be well controlled with the high bond strength to the substrate.

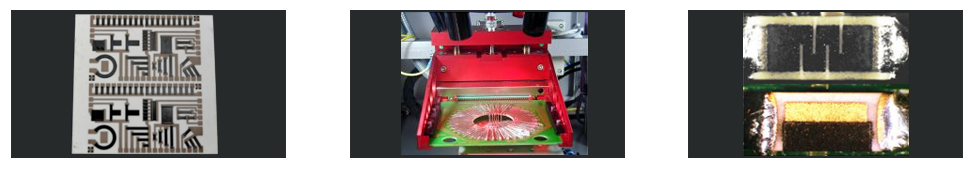

A laser trimming system speeds up, automates and increases the accuracy of your trim application. We builds a system from modules, customized to your requirements, providing optimum cost and performance. We supplies modules for integration into OEM systems or production lines, as well as complete stand-alone systems with instrumentation, electrical contacting and automated handling

Enhance you product performances by trimming

Laser trimming is a way of achieving precision alteration of the attributes of an electronic circuit by laser cutting. A laser removes material from the appropriate component and thus adjusts its value. A lateral cut into an SMD or hybrid resistor increases its resistance. Removing part of the top electrode of a capacitor decreases its capacitance.